Love at first sight: The Crossbow at SEMA 2014

Love at first sight: The Crossbow at SEMA 2014

The best part of building custom race buggies is that they are custom. You can build anything you want. However, the worst part about building custom race buggies is that, well… they are custom, so you have to build most of what you want!

Steve Zlotnicki (ESAB product line manager) was a little protective of the Crossbow during SEMA 2014.

Steve Zlotnicki (ESAB product line manager) was a little protective of the Crossbow during SEMA 2014.

At LetzRoll Offroad Racing, like most small shops, physical space and funds are at a premium. A fast, easy, affordable plasma cutting solution had always been a dream for our shop, but it was a dream that was just a little bit out of reach.

Enter the new ESAB Crossbow. We were first introduced to this machine at the 2014 SEMA Show in Las Vegas. They say, "What happens in Vegas, stays in Vegas," but this was one thing we did NOT want to have "stay in Vegas."

Here's why: The first day on the SEMA floor, LROR employee and codriver extraordinaire Jason Hurst drew up a piece on his laptop computer to be cut. He took the design over to ESAB's Steve Z. at the Crossbow on a thumb drive... Less than 30 minutes later we were holding a finished part for the race car.

Mind. Blown.

Jason Hurst with LROR fully approves of the Crossbow.

Jason Hurst with LROR fully approves of the Crossbow.

We needed the Crossbow in Phoenix... especially with two new cars being built... and we needed it now. We were stoked and couldn't wait to get this machine in our shop!

Now we run the Crossbow almost every day. The ability to think up and design the perfect bracket for a custom job we have in front of us, and then have it cut out right before our eyes, is not only satisfying, but efficient.

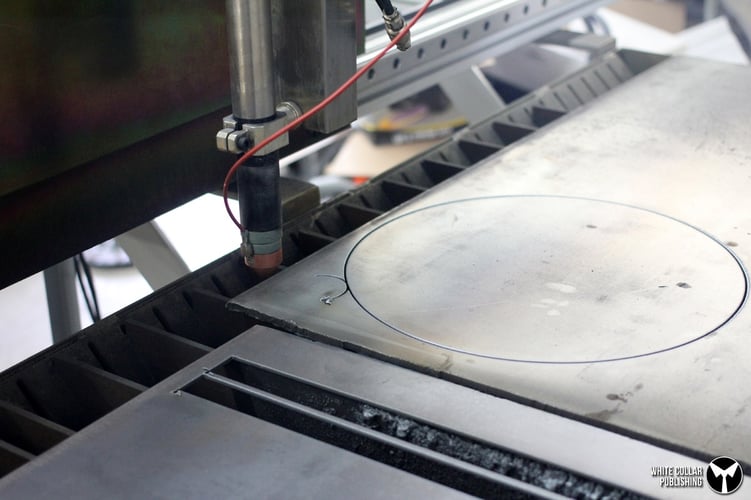

The Crossbow is used almost daily at the LROR shop.

The Crossbow is used almost daily at the LROR shop. Before we brought the Crossbow in, we did things one of two ways:

1) We drew pieces out on cardboard, traced them on pieces of steel, cut them out by hand, then went back and cleaned them up. (There were a lot of limitations in making accurate and precise pieces, plus the time ramification of going back and having to clean everything up was frustrating... an unfortunate reality in most small shops.)

2) Our only other option was to use a small CNC 2x2 table that was much more... "primitive." It got the job done for some stuff, but it really wasn't able to hold a candle to what we've been able to achieve with the Crossbow.

Old school cardboard templates, which now go to design instead of tracing.

Old school cardboard templates, which now go to design instead of tracing.

That's because the Crossbow is incredibly easy to use and operate. We are a custom shop even beyond the race cars, so most of the stuff we do is one-off. We use a variety of sizes and thicknesses of steel and aluminum.

With the Crossbow, we can have various pieces of material on the table and simply move the torch to where we need it to make a one-off bracket, then just adjust it to a different size or thickness and make the next piece we need for the project.

Even Jason is sometimes amazed at how easy it is...

Even Jason is sometimes amazed at how easy it is...

The software that comes with the Crossbow is intuitive and easy to use, as we learned at SEMA. It's great that you can have a laptop right there so you're not forced to use a dedicated computer when you need to make something quick.

At LetzRoll, we build some of the most unique, purpose built vehicles currently known in the automotive industry. The Crossbow allows us to deliver a quality product, consistently, that we once had to make by hand. We can duplicate projects as well as design and come up with new solutions fast.

Jeff Wilstead welding up custom cut mounting brackets.

Jeff Wilstead welding up custom cut mounting brackets.

The Crossbow also allows us to do a lot of things we simply could not do before - either by hand or with our old table. The setup that we have now is basically a 5 x 4. We can even draw full axle trusses (if they aren't available from ARTEC Industries) and cut them out within two hours. Before, that process would've taken a couple of days.

Andrew McLaughlin picking up a custom piece for a build.

Andrew McLaughlin picking up a custom piece for a build.

We use the Crossbow on just about every project we have in the shop - whether it's a one-off bracket that starts with just an idea, or one of the more standard parts we use that have become LetzRoll's "signature" style.

We brought the Crossbow into the shop about six months ago, and it made a huge impact immediately. The return on investment has been fantastic - and that's very important to our shop, where we have to choose where to invest in equipment wisely.

Jason lines up the torch to cut a part on the Crossbow.

Jason lines up the torch to cut a part on the Crossbow.

And then there's the benefits for our race cars... Custom race cars are their own experience and their own beast (as we recounted in an earlier blog).

Everything on our race cars is one-off. For instance, we have the chassis and we want to mount brakes on it, so we order the parts for the brakes, but we have to come up with how to mount the brake calipers to the axles.

Now, with the Crossbow, we draw the brackets up, cut them out on the machine, and mount them right up. We've had two instances where we've messed up the brakes and in two minutes we can make a new set of brackets. Duplication wise, the Crossbow has been fantastic.

LROR pieces cut out for our open house. Visitors welded take-home pieces and tried out equipment.

LROR pieces cut out for our open house. Visitors welded take-home pieces and tried out equipment.

Half of the 4493 race car was probably built with brackets and gussets from the Crossbow... everything from mounting the seatbelts, to GoPro mounts, brakes, radio mounts and light mounts. It's made the process of maintaining the race car less frustrating, less cumbersome, and a whole lot less aggravating.

Now we don't have to recreate something from scratch or go find the cardboard template each time. We created it once, we did a good job, and we can just replace it.

Crew Chief getting it done on the 4493 buggy.

Crew Chief getting it done on the 4493 buggy.At LetzRoll, we can't imagine - and don't want to imagine - the shop or the race team without the Crossbow. It's one of our favorite pieces of equipment, and well worth the investment. It has made a big impact on the team, the shop and the bottom line.

The portability of the Crossbow also allows us to provide support for ourselves and other teams at the races, such as the King of the Hammers.

Next up is the Ultra4 Glen Helen Grand Prix in July. Be sure to come by, say hello, and check out the Crossbow and other great equipment. Just look for the ESAB truck and LetzRoll Offroad Racing.

Are you Ready to Roll?

Like what you read about the ESAB Crossbow? Take advantage of this special offer!