“Racing is life. Anything before or after is just waiting.” ~ Steve McQueen

I love this Steve McQueen quote, but it would make more sense if it read, “Racing is life. Everything before or after is just prep.” It’s nine days until we leave for the Lakebed and the Nitto King of the Hammers. The wait is almost over and the builds are almost complete.

The LetzRoll Offroad Racing shop has been a madhouse of activity, creativity, and work. We started with an almost impossible task of building not one, but two new racecars for the 2015 season - the new ESAB Welding & Cutting / Yukon Gear & Axle 4493 IFS car, and the ESAB Welding & Cutting / Pit Bull Tires #4511 Modified car.

One of the best things of any race team, club, shop, or league is the camaraderie and brotherhood that develops. King of the Hammers is no exception. The frantic pace of build and prep creates a bond like no other. This week, our brothers from the East arrived. Mike Robertson (LetzRoll Offroad Racing UK) arrived from the UK, followed shortly by Joe Pierce (yes, THAT Joe Pierce) from Maine. With reinforcements, the builds have taken off at warp speed. Nine days left, but we’re going to make it… barely.

The 4493

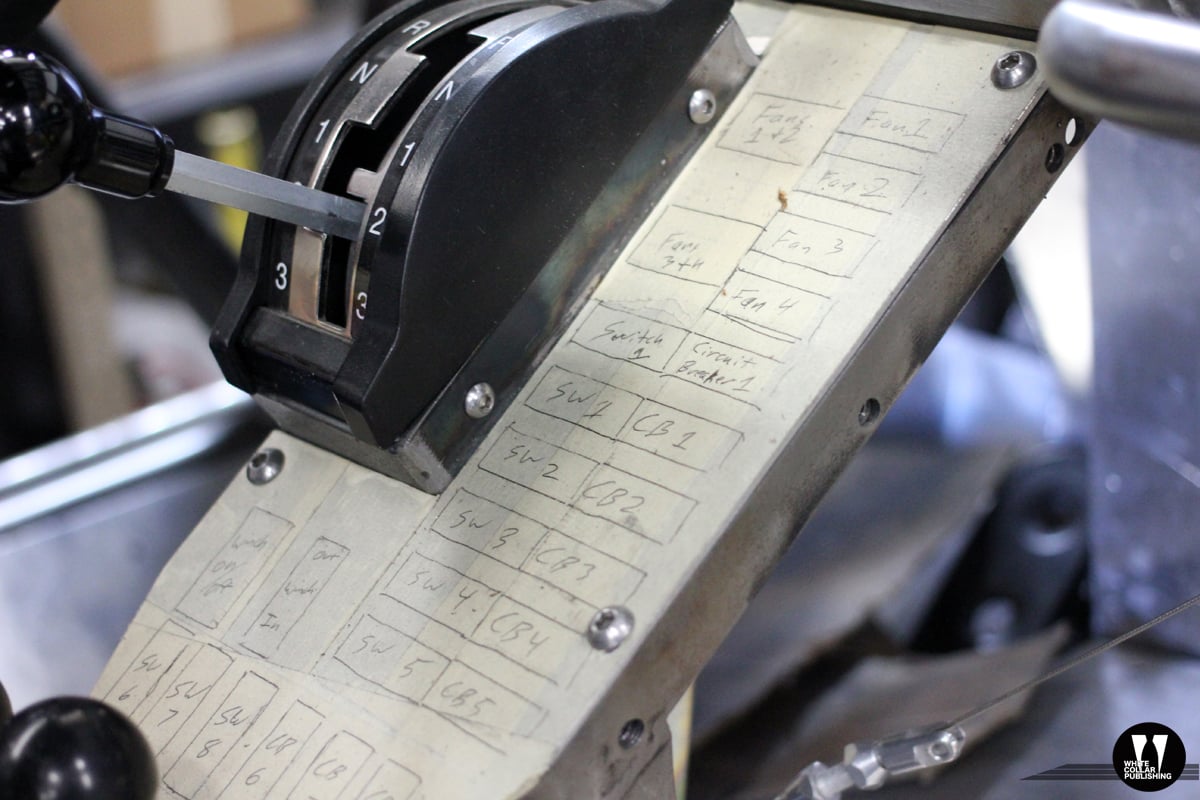

The main chassis was completed and the real work commenced in October. As with most builds, the heaviest lifting are the things you can’t really notice. It takes weeks to complete the wiring, plumbing, switches, coms, and detail work. Custom fabrication requires customized tabs, mounts, parts, and support pieces.

The ESAB Crossbow system has been a life (and build) saver time after time. Mounting a Sparks Pro Racing TH400 transmission, along with the rear mount engine, required strong and specialty mounting to hold up to the abuse of desert racing. We have also reached the point where our Rugged Radios intercom and race radio system have been installed and tuned.

Layout for switch and breakers panel.

The team experienced a huge victory when everything was connected and we fired up the engine for the first time. Despite your head telling you everything is going to be okay, there is nothing quite like hearing that engine for the first time and confirming it. From there, the build moved quickly and we’re within a few days of being able to do shock tuning. The car now drives under its own power and will be ready for the King of the Hammers race on Feb 6th. The remaining nine days before departure are all centered around completing the detail work, ensuring everything is properly functioning, and triple checking the systems and safety equipment.

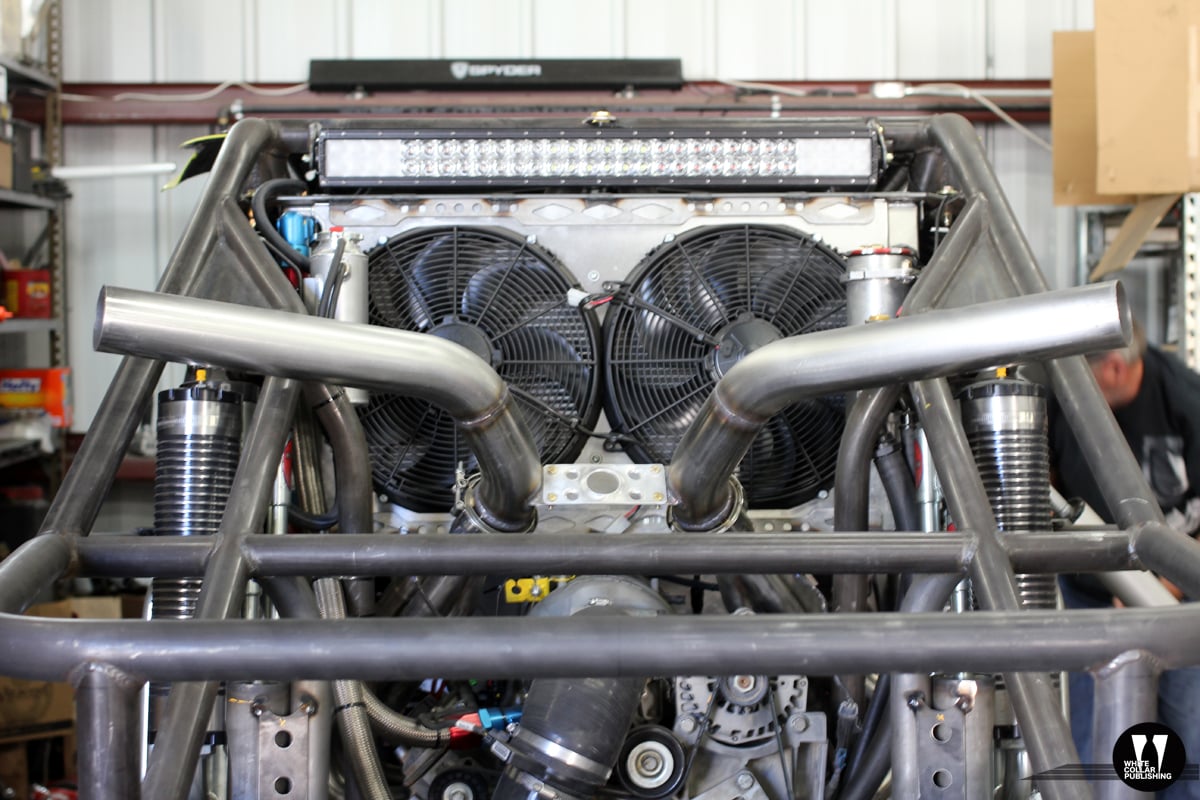

Beginning of the exhaust layout.

Since the buggy has been sheltered in the garage being built, the team rallied around for a day in the sun as we ran the buggy up and down the road in front of the shop and then took a minute to soak up a sunbeam. Arizona in January is pretty awesome… but not as awesome as seeing your main car run for the first time.

Every successful program starts with a team.

The 4511

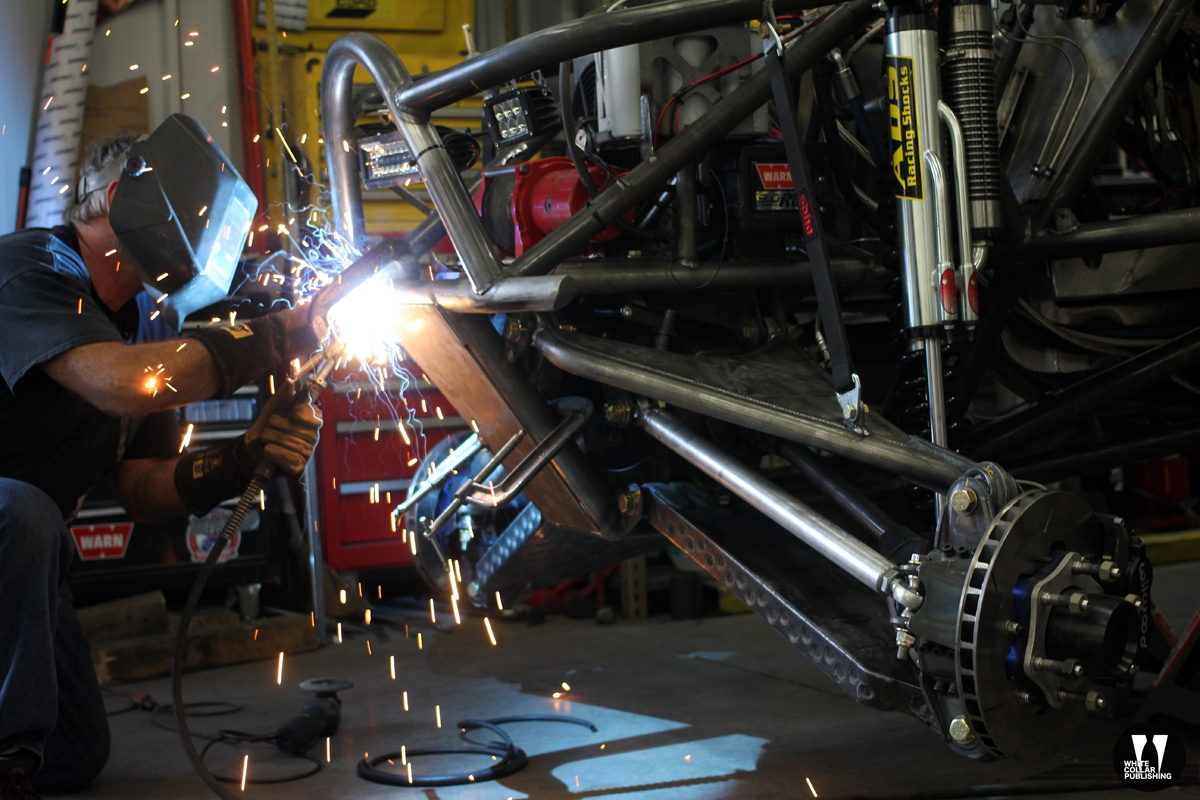

This is where we needed the reinforcements. “Ginger Mike” Robertson flew in from Wales, UK to be with the team the last two weeks before the race and to help thrash on the 4511. The chassis went to final weld on January 12th… only 3 weeks before the team leaves for King of the Hammers. EVERYTHING still needs to be completed on the car and the pressure is mounting.

There has been so much doubt on social media that the team can pull this off, that an #ibelieve hashtag campaign has been instituted to show support. The first day this car drives may very well be the day it is driven onto the trailer to leave for KOH.

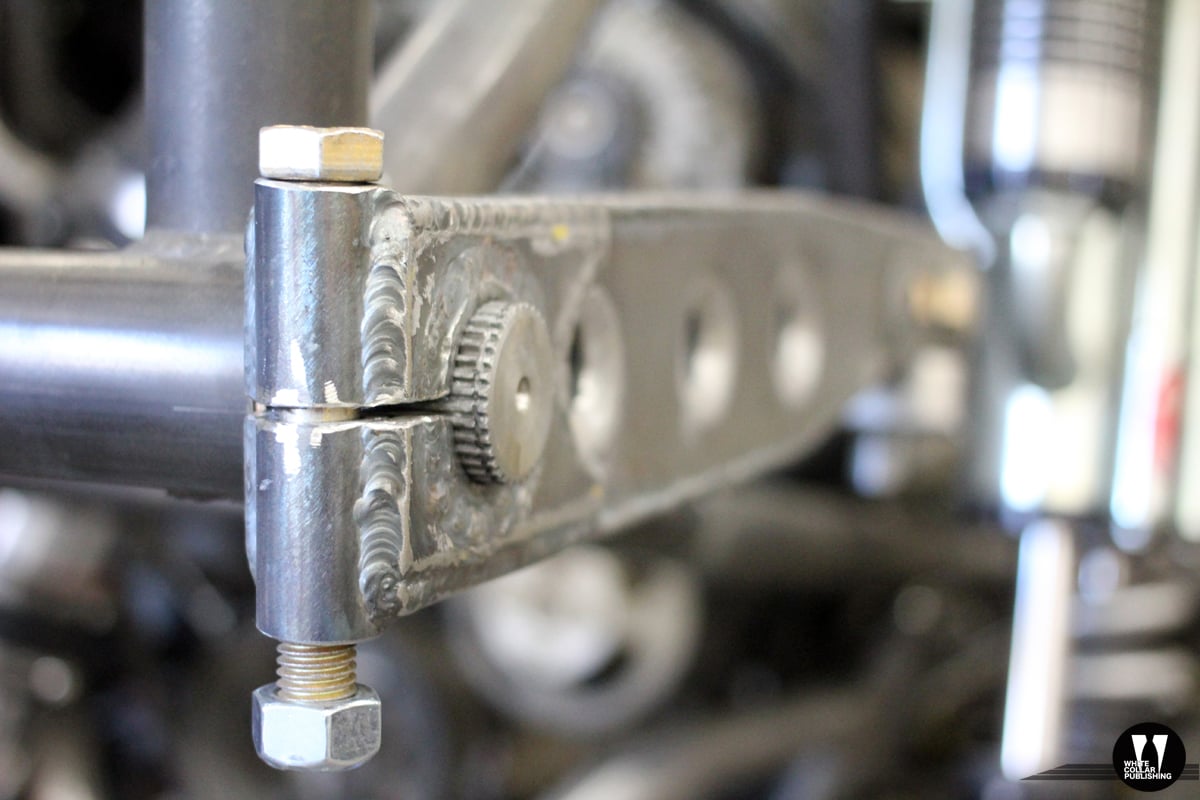

With the chassis complete, the team has been working double shifts, around the clock mounting the engine, transmission, and transfer case. Custom mounts, supports, and spreaders are all being cut, built, and welded. The ESAB welders and cutters are getting a workout, as everything starts with the welder. Seat mounts are in and the electrical and dash components are being crafted, as well as shock mounts and reinforcement.

Custom front shock mounts.

Concurrent with building the functionality of the car, the team has also been working on skinning the buggy so it can get its distinctive ESAB yellow wrap in time for Hammers. The hood, grill, and cowl are all fiberglass molds, but the side panels and rear tailgate are made from Lexan. Strong, lightweight, and easy to replace if damaged, Lexan allows for flexibility in shape and design.

By 4500 class rules, all vehicles must resemble a production vehicle. The 4511 is modeled after a Jeep TJ. To allow for the maximum amount of up travel from the ADS Off Road Racing shocks, the front shock mounts extend up through the hood, blending form and functionality.

Hood, cowl and grill fitting for the 4511.

Upper shock mounts peeking through the hood.

The 4511 team also hit a big milestone and fired up the LQ9 for the first time this week. We’ll be pairing it with a Dynomax Performance Exhaust system running duel exhaust to just behind the rearmost passenger area.

Jeff Wilstead, lead fabricator at LROR.

Will we be ready in time? Follow us on Facebook and Instagram to keep up with our countdown to KOH and support the #ibelieve campaign!

Pausing to see the beauty

Welders create. Sometimes, the process itself can be art. Thank you for all you do and the things you create. We tip our welding helmets to each and every one of you. This series is from a late night thrash session at LetzRoll Offroad Racing, crafted with ESAB products.