Seven weeks until the Lakebed and the 2015 King of the Hammers. Six until we leave Phoenix… the pressure is starting to set in. Yet, in the middle of all this, we had a chance to connect with friends and family.

Let’s recap: 1.) Andrew has a brand new IFS car that is unproven, unfinished, and untested. 2.) Alan has a brand new car that isn’t even final-welded yet. 3.) Preparation wins races, yet we have no time for testing.

Are you Ready to Roll? This is going to get exciting.

Man and machine.

Man and machine.

The 4493:

The 4493 IFS chassis is starting to fill up with all the little stuff that makes these cars go. The team has been working hard on plumbing and wiring. The first drive date is starting to be talked about in the shop, which is a good thing. Shock tuning on the Lakebed in Johnson Valley is only three weeks away. Tuning the shocks and dialing in the performance is paramount in these cars.

Jeff and Crew Chief planning a skid plate for the 4493.

Jeff and Crew Chief planning a skid plate for the 4493.

There is a lot of stress as we wait for some critical parts to be machined, heat treated, and shipped, but we are confident in our partners and know they are doing everything they can to get stuff to us as fast as possible and without any compromise.

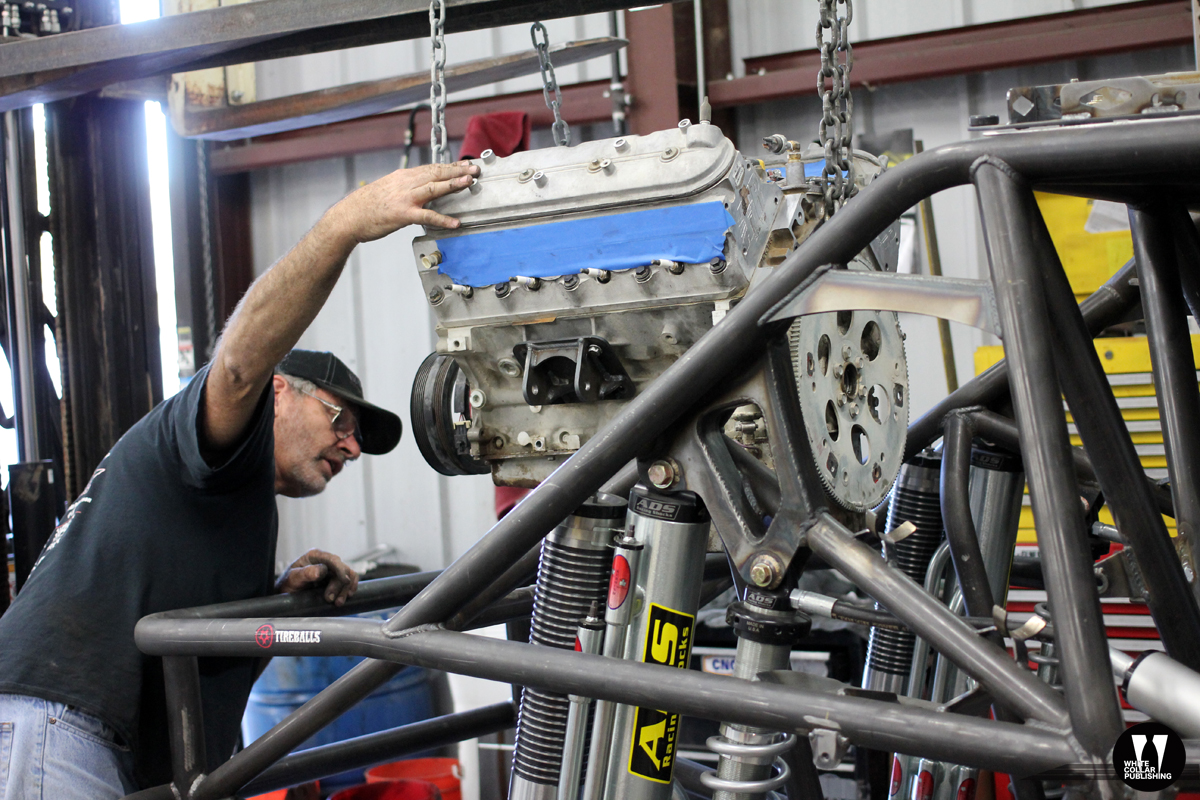

The rear mounted, reverse racing engine creates some unique challenges when it comes to the transfer case and the rear driveline. Crew Chief is owning the process and ensuring alignment along with performance. A massive cooling system is also required for the power steering system.

Crew Chief guiding the engine into the 4493.

Crew Chief guiding the engine into the 4493.

Good thing there is still plenty to keep us busy. The timing sure feels right, but it’s going to be difficult to race an unproven car in the biggest race of the year. Despite what your head tells you, muscle memory and trust have not been formed in the new car yet, and sometimes that’s all you have in the heat of the moment…

Measuring for rear limiting straps.

Measuring for rear limiting straps.

The 4511:

The 4511 solid axle Jeep is in the Modified Class, which has limits and rules in both build and performance. By rule, the frame has to be square tube from the motor mounts to behind the passenger compartment. Truly a builder class, that’s how the car starts. Tube on a table.

Starting from scratch. Laying out the 4511.

Starting from scratch. Laying out the 4511.

Additional class requirements include no more than 14” shock travel, mechanical steering (so we’re planning for a steering box with hydro assist), and 37” tires. These rules impact the chassis layout and the space requirements significantly.

Building Modified cars is one of Andrew’s favorite things in the world to do. (Yes, that was sarcasm). The challenge, however, is one of the things that adds so much satisfaction to the final product. Class limitation rules really require creative solutions to maximize performance and still meet class guidelines.

Andrew thinking about how much he loves the Modified class.

Andrew thinking about how much he loves the Modified class.

4511 is making some good headway, with the main cage layout completed in a week. We are starting to see some of the critical build components (radiator, engine, transmission, shocks, fuel cell, etc.) trickle in so we can start the process of mounting them.

The 4511 will be running the rear axle the team built on Two Guys Garage back in October. Paired with a tuned LQ9 engine and a 4l80 transmission (custom built by Sparks Pro Racing - just look for the purple transmission), the 4511 will be one of the fastest, lightest cars in its class.

The lines of the 4511. The ghost of the chassis.

The lines of the 4511. The ghost of the chassis.

With some luck and hard work, the next few weeks will be consumed with filling in the main voids of the chassis with these parts. We are confident in the design, but the clock is against us. Final weld needs to be completed, as well as fuel system layout, electrical, body panels, and the front axle.

This car will not be ready in time for shock tuning, so if we make our deadline, it will be racing cold… no seat time, no test time, limited shock tuning. We like to live on the edge.

Rear view of the 4511. Fuel cell, radiator, and spare tire space.

Rear view of the 4511. Fuel cell, radiator, and spare tire space.

The Open House:

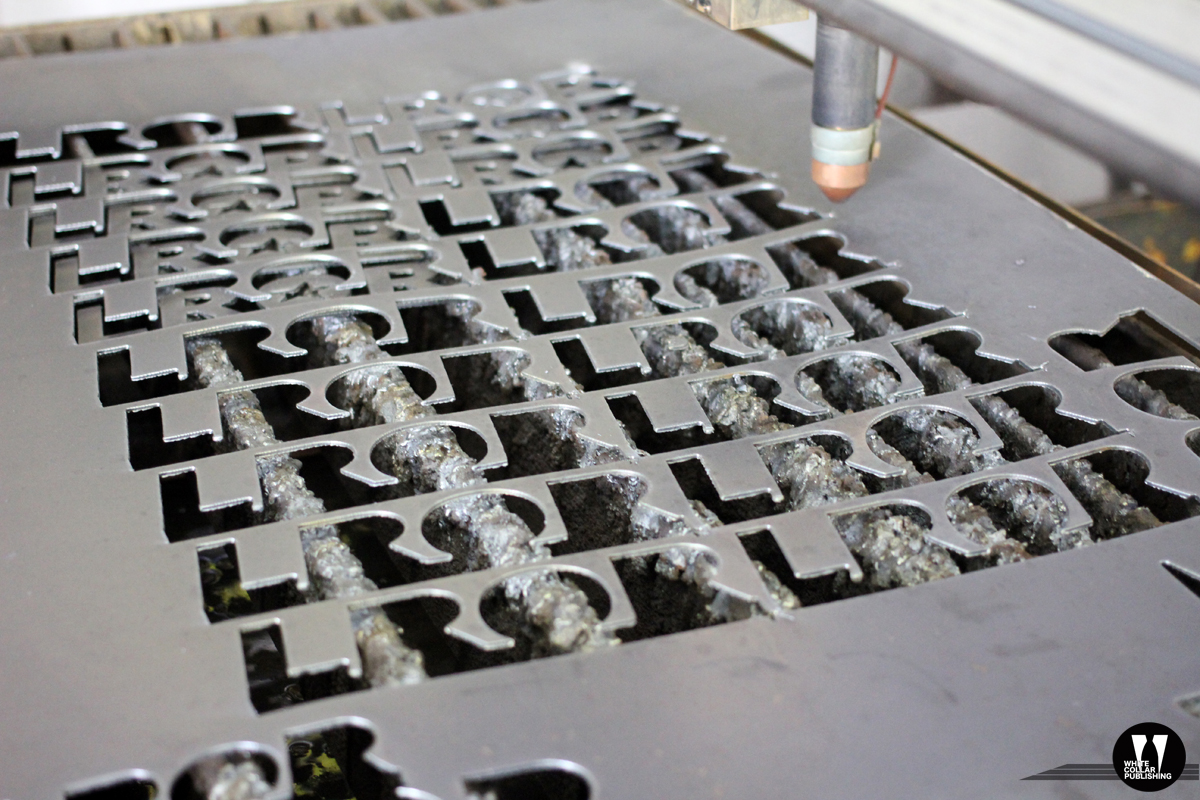

Part of what makes the offroad community so great is the people… from all walks of life, with all types of vehicles, coming together around something they love. LetzRoll recently had an open house, axle workshop, and welding workshop to showcase the new racecars, with customer rides, Yukon Gear and Axle products, ESAB Welding and Cutting equipment, and ADS Off Road Racing shocks.

Hands on welding at the LROR open house.

Hands on welding at the LROR open house.

There were burgers, shenanigans, RTI ramps, friends, and fun… bringing the offroad community in Phoenix, Arizona together for a few hours. Jeeps ranged from fairly stock JKs to complete buggies, yet everyone enjoyed hanging out and learning. Many of the people were first time welders, getting to weld and cut under the guidance of experienced fabricators.

A couple that welds together, stays together. Joe and Jen at the LROR open house.

A couple that welds together, stays together. Joe and Jen at the LROR open house.

So, to recap… we have two unfinished cars and six weeks until we leave for the lakebed, but even in the midst of intense King of the Hammers prep, there is always time for friends and fun. After all, that’s what this is all about. We’re always Ready to Roll.

Using the Crossbow to cut out pieces for the open house welding class.

Using the Crossbow to cut out pieces for the open house welding class.

Stay tuned for car specs in our next blog. We’ll be breaking down the components and equipment going on each car.